Wood Powder Machine Features:

High working speed: the machine working with high speed at least 2900r/min.

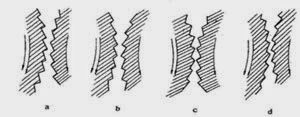

Reasonable crushing principle: the machine adopts high-speed impact, sharp cutting, interval grinding and flowing grinding to get fine crushing effect.

Advanced design: low investment, low energy consumption and noise; it can also improve the production efficiency and working stable.

Adjustable fineness: the fineness can be adjusted between 20 meshes and 325meshes.

Reasonable and compact structure: the whole equipment is consisted of main host, blower, powder collector and dust collector, etc. It is safe and convenient to operate.

The

wood grinder can grind material into powders or granule, fibrous material of different fine degrees(from10-525meshes)the rate reaching100% without slag.

Wood powder machine raw materials:

The machine mainly deal with solid matter in 3 level hardness, such as soft mineral, brittle material, tough materials, fiber material and some material easy to condense into block.

Suitable for: miscellaneous wood powder, bamboo powder, cork powder, polyvinyl chloride (PVC plastic)the tooth material, dyestuff, leather, mica, refined cotton, seawater product, spices, feed, rice shell, peanut shells, nut shell, cavings, pesticides, charcoal, hard foam, fine tires line etc.

Wood powder machine start working process:

1. Before start working, you should strictly check whether

wood powder making machine each part installation can meet requirements or not, metal material is forbidden fall into the machine, push belt to testing the machine by hand, check whether there are vibration or not.

2. Start sequence: first start blower, then main host; stop working you should first stop main host then blower;

3. Keeping even feeding, feeding size according raw material hardness, hard material diameter should low than 3cm, forbidden metal block feeding into discharge opening.

4. During

wood powder making machine working process, blower shouldn't overload, keeping normal working.

5. You should often check blade, grinding board abrasion degree, once there are serious abrasion on the blade, you should replace them in time.