Dear Friends:

Thanks for your attention to kefan mining machinery company. Tomorrow we'll have three days holiday for national May Day. Any questions pls leave me messages, once I saw them, I'll give you answers as soon as possible!!!

2014年4月30日星期三

2014年4月29日星期二

What's wood powder machine whole equipments structure composition?

2. Wood powder making machine draft fan is centrifugal blower, main used to provide suitable airflow pressure and airflow capacity for the whole machine and play dust collecting role.

3. Wood flour machine dust collector main host is a box, box bottom set a dust discharge opening, box have to install inner a vertical frame. Vertical frame top part with full bag, dust collector receive contain dust gas from centrifugal separator. As filter bag dust collector working efficiency can achieve more than 99%. So, wood powder making machine working with non pollution condition.

2014年4月23日星期三

Cement rotary kiln

Cement rotary kiln under high temperature condition with heavy loading working with low speed, the auxiliary equipment maintain and heating processs control level related to rotary kiln safety and working efficiency. Transmission device maintain main important is the equipment lubrication, working condition, dynamic detection and gear pinion mesh fineness; supporting device instalation fineness determined whether rotary kiln can reliable working or not, during working process. Whether sealing device good or not straightly effect rotary kiln heating process and working investment. According to rotary kiln daily maintenance date, strength it make it convenient for the equipment mangement working.

Wet type cement rotary kiln working process: change raw material into material slurry with 30-40% moisture. As material slurry have fluidity, so, each raw material with good mixing property, raw material with uniform ingredient, making clinker with high quality, it's wet type production main advantage. Well dry type cement rotary kiln is change raw material to powder with humidity low than 1%. Thus, it need less water evaporation heat value. But dry type cement kiln raw material is dry powder, bad fluidity than material slurry, so raw material with bad mixing, uneven ingredient.

Cement rotary kiln advantages:

The working system adopt domestic the most advanced hydraulic gearwheel device, adopt high measurement accuracy measurement column pump, high accuracy speed adjust valve and contact type graphite block sealing device and other domestic advanced technical. Convenient to operate, reliable working. Compared with the same specification equipment, working efficiency improved 10%, production capacity improved 5-10%, heat consumption decreased 15%, kefan is an ideal cement rotary kiln for clients to chose.

2014年4月22日星期二

What technical advantages do high pressure grinding mill have?

2. Adopt advanced grinding system, high pressure grinding mill has recently the most advanced grinding system, making the machine realized intelligent. In grinding system, high pressure mill configurate vertical swing grinding roller device, thus, when grinding roller and grinding ring working time keep a balance condition, form regulat uniform line contact grinding area.

Powder grinding mill equipments like high pressure grinding mill can lift grinding roller and grinding ring height, increase grinding contact area, at the same time airflow capacity and final products collect system become negative pressure and secondary high working efficiency dust collector, thus thorough collect final products. Adopt enforce turbine classifier, making final products size from organic 80-325 mesh range expand to 80-800 range.

Cement rotary kiln structure installation and testing:

Cement rotary kiln is a equipment used to process cement clinker dry and wet production line, and also can be used in metallurgy, chemical, construction refractory material, environmental protection and other industrials. The main spare parts: working cylinder, supporting device, transmission device, movable kiln head, kiln tail sealing device, coal injection pipeline device, kiln liner, kiln tail seals, kiln head and fuel device, etc.

Cement rotary kiln installation and testing:

After purchase cement rotary kiln, we should careful installation and testing the equipment, include the following sides:

1. Familiar with drawing picture:

Before instal rotary kiln, we should first familiar with relative drawing picture, working site water, electric, road and other safety effect, make sure power energy position and temporary power energy position.

2. Lifting, transporting side:

During cement rotary kiln installation process, as it is very heavy, so, we should make a certain prepartion and transporting tools in advance, to prevent the unknown troubles.

3. Working people requirements:

When installation, as cement rotary kiln working cylinder is too big, you should avoid cross working, as when we arrange the working site, rotary kiln has a certain distance to the underground, so, we should specially pay attention to safety side. To get a certain installation effect, there should better have security officer supervision, technical guide.

2014年4月21日星期一

High pressure roller mill application and working principle:

High pressure suspension grinding mill main used to process metallurgy, construction material, chemical, mine and other industrial material powder grinding, can grind limestone, marble, calcite, feldspar, sand slag, dolomite, granite, iron ore, clay, kaolin and other mohs hardness low than 9.3, wet humidity low than 10% non-flammable, non-explosive materials.

High pressure suspension grinding mill structure: main host, analyzer, pipeline device, blower, jaw crusher, bucket elevator, electric vibrating feeder, electric control device and motor, etc. Main host inner structure: plum frame, vertical axle-bearing, balde, blade barrel, grinding roller assembly and other device. Main host working process through transmission device drive center shaft rotation, shaft top connect plum frame, frame top install grinding roller assembly and form swing pivot. Plum frame bottom install blade system, the position located grinding roller bottom port, during blade and grinding roller co-rotating process, feeding raw material between grinding roller and grinding ring, form cushion material layer, the layer suffering grinding roller rotation produced centrifugal force(extrusion force) grinding raw material and achieve powder making goal.

When using high pressure suspension grinding mill, if raw material too big, you can use PE250*400 jaw crusher, after coarse crush, output material transport to silo by elevator, then through vibrating feeder feeding to high pressure suspension mill uniform. Generally, we using D200*7m standard configurate elevator, and we can also making improve according to clients different requirements. High pressure roller mill final products size can be adjust from 30 mesh to 350 mesh according to actual condition to adjust and different fineness determined different production capacity.

High pressure suspension grinding mill structure: main host, analyzer, pipeline device, blower, jaw crusher, bucket elevator, electric vibrating feeder, electric control device and motor, etc. Main host inner structure: plum frame, vertical axle-bearing, balde, blade barrel, grinding roller assembly and other device. Main host working process through transmission device drive center shaft rotation, shaft top connect plum frame, frame top install grinding roller assembly and form swing pivot. Plum frame bottom install blade system, the position located grinding roller bottom port, during blade and grinding roller co-rotating process, feeding raw material between grinding roller and grinding ring, form cushion material layer, the layer suffering grinding roller rotation produced centrifugal force(extrusion force) grinding raw material and achieve powder making goal.

When using high pressure suspension grinding mill, if raw material too big, you can use PE250*400 jaw crusher, after coarse crush, output material transport to silo by elevator, then through vibrating feeder feeding to high pressure suspension mill uniform. Generally, we using D200*7m standard configurate elevator, and we can also making improve according to clients different requirements. High pressure roller mill final products size can be adjust from 30 mesh to 350 mesh according to actual condition to adjust and different fineness determined different production capacity.

2014年4月18日星期五

High pressure suspension mill grinding chamber shape and liner abrasion relationship:

For powder grinding mill machine, different powder grinding chamber determined different liner abrasion condition for the same kind powder grinding mill.

High pressure suspension grinding mill grinding chamber abrasion has the following analysis:

a. During high pressure roller mill start working process, transport to the machine parallel zone will stack too much raw material at the feed opening, later will decrease sharply. Thus, parallel area suffering strong abrasion and high pressure suspension mill working several day, parallel area will be change gradually.

b. With liner board abrasion and powder grinding chamber layout change degree, along the powder grinding chamber height grinded raw material with uniform distribution. In liner limit abrasion range all the machine exist grinding chamber layout size change condition, especially later period hasn't parallel area, the whole grinding chamber completel lost organic layout. Besides, feed opening size about decrease 1.4-1.7 times, feed opening processed the most raw material. As without parallel area make output products with bad quality, the production capacity will be decrease.

In a word, as high pressure suspension mill uneven liner abrasion, powder grinding chamber will lost organic shape, lead to liner with lower using life and decrease technical economical standards.

2014年4月16日星期三

What's raymond mill plum frame function and deform reason?

Generally condition, as long as raymond mill normal working, there is no hard material fall into the grinding area and stumble main shaft, plum frame won't be deform. Raymond mill main host through transmission device drive center shaft rotation, center shaft top connect plum frame, roller shaft installed on the plum frame, plum frame drive by main host transmission device and fast rotation, grinding ring fixed, electric vibrating feeder make raw material fixed quantity, uniform and continous feeding to grinding chamber, grinded by grinding roller and grinding ring force. As airflow from grinding ring bottom tangentially inhalation, through grinding roller and grinding ring grinding area, inclusion powder dust feeding raymond mill top wind classifier. Plum frame top installed three grinding roller, not only revolving around the central axis, but also grinding roller itself due to friction rotation. Thus, through friction and raw mateiral sedimentary lead to plum frame unstable working.

Henan kefan produce raymond mill equipment: raymond grinding mill, ultrafine micro-powder mill, ball mill, high pressure suspension grinding mill, etc. Contact us for discount!

2014年4月15日星期二

Cement rotary kiln

Rotary kiln blongs to construction material equipment, according to different raw materials, it can be divided into cement rotary kiln, metallurgy chemical rotary kiln and lime rotary kiln.

Cement rotary kiln is cement clinker dry and wet type production line main equipment. Rotary kiln is widely used in metallurgy, chemical, construction refractory material, environmental protection and other industrials. The plant composed by cylinder, supporting device, gear wheel supporting device, transmission device, moviable kiln head, kiln tail sealing device, coal injection pipeline device and other spare parts. Rotary kiln working cylinder and horizontal shown a certain inclined degree, the whole cylinder supporting by supporting wheel device, and have control cylinder moving supporting device, transmission system except setting main drive, but also set main power energy, when power cut kiln cylinder can still rotation, prevent cylinder bending and deforming auxiliary transmission device, kiln head, kiln tail sealing device adopt advanced technical, make sure reliable seals.

Our factory produced rotary kiln has features of durable structure, stable working, output high quality products and can provide user advanced high efficiency vertical preheater and five star cyclone preheater.

Rotary kiln besides calcination cement clinker, but also used to calcinate clay, limestone and so on. During refractory material production process, adopt rotary calcine raw material, make it with stable size, increase strength, re-process and forming. During ore beneficiation process, using rotary kiln magnetic and roasting poor iron, making raw ore weakness magnetic change into strong magnetic, convenient for magnetic-separation. In chemical industrial, using rotary kiln produce soda, calcine phosphate fertilizer, etc, this method has features of low energy consumption, power energy-saving, no need sulfuric acid and can utilize low grade phosphate ore and so on.

Besides, in environmental protection side, utilize cement kiln incineration dangerous waste, rubbish, this not only decrease waste material, harmless, bust also make waste material utilization to become fuel, save coal powder, make sure waste material to be resource.

Our factory produced rotary kiln has features of durable structure, stable working, output high quality products and can provide user advanced high efficiency vertical preheater and five star cyclone preheater.

Rotary kiln besides calcination cement clinker, but also used to calcinate clay, limestone and so on. During refractory material production process, adopt rotary calcine raw material, make it with stable size, increase strength, re-process and forming. During ore beneficiation process, using rotary kiln magnetic and roasting poor iron, making raw ore weakness magnetic change into strong magnetic, convenient for magnetic-separation. In chemical industrial, using rotary kiln produce soda, calcine phosphate fertilizer, etc, this method has features of low energy consumption, power energy-saving, no need sulfuric acid and can utilize low grade phosphate ore and so on.

Besides, in environmental protection side, utilize cement kiln incineration dangerous waste, rubbish, this not only decrease waste material, harmless, bust also make waste material utilization to become fuel, save coal powder, make sure waste material to be resource.

2014年4月14日星期一

High pressure suspension mill detail informations:

High pressure suspension mill raw materials and products properties:

The materials should be non-flammable and non-explosive. Examples of the materials are: quartz, feldspar, barite, fluorite, dolomite, garnet, carborundum, bauxite, zircon, marble, calcite, iron ore, rock phosphate, coal, ceram, slag and so on (400 kinds of materials).

The materials should have the hardness less than 9.3 in Moh’s scale and humidity less than 6 percent. The granularity of the end products can be changed from 30 to 425 meshes.

High pressure suspension mill features:

1. Unique design, widely applications. Compared to other mills with the same power, the production capacity of is increased 20-30%;

2. Eco-friendly. Dust cleaning can fully meet national standards.

3. Good airtightness. The grinding rollers apply the overlapping and multi-level air protection to make sure the efficiency and long working life;

4. Low operation cost. The wearing parts apply high quality materials to lengthen the grinding rollers and rings' working life. And also decrease the customers' investment cost;

5. Increase the wearing parts utilization. To make sure stable productions capacity and output fineness, customers can adjust high-pressure spring length and keep the invariable pressure between grinding rollers and rings.

High pressure suspension mill working principle:

High pressure suspension mill and raymond mill have the same working principle. When the machine works, the grinding roller, under the action of high pressure spring and centrifugal force, rolls close up to grinding ring, its rolling pressure is 1.2 times higher than that of raymond mill. When the grinding roller and grinding ring reach a certain degree of abrasion by adjusting the length of high-pressure springs to keep the constant grinding pressure between grinding roller and grinding ring, stable output capacity and fineness are guaranteed.

2014年4月13日星期日

How does raymond grinding mill grinding tooth incline degree form?

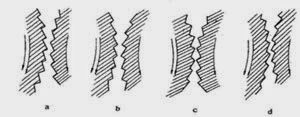

Raymond grinding mill two roller grinding tooth at grinding area both side, relative to material form many crosspoint, under grinding roller rolling distance smaller than raw material formed coverage length condition, raw mateiral at crosspoint suffering bigger shear force. When raymond grinding mill grinding area with many crosspoint, grinding area material suffering shear force average chance will increase, equipment crushing ability will increase.

Under other same condition, big incline degree produce many more crosspoint in grinding area, material in raymond grinding mill grinding area will suffering stronger crushing degree, fragile cortex, bad products quality and low energy consumption. But to meet low energy consumption requirements, it should select bigger incline degree.

Raymond grinding mill grinding tooth joggle details please look at the attached picture.

2014年4月11日星期五

Wood powder machine full technology:

1. You can add a new type material, has function of soundproofing, radiating. So, during the machine using process, low noise, no vibration, good appearance, stable and durable, high production capacity, compare with traditional wood powder making machine, production efficiency improved 50%, it's recently other powder grinding machine can't replace high technical ideal equipment;

2. The machine feed opening adopt self-priming feeding, replaced traditional hammer crusher straightly feeding, ignore input metal block lead to serious damage disadvantages and make sure safety production.

3. The wood flour machine with fine processing technology, adopt doule layer airframe mezzanine.

4. Inject running water to cool wood powder machine.

The machine has features of widely outlet products fineness range, strong complex property.

Wood powder making machine structure principle:

1. Adopt high speed impact, sharp cutting, gap grinding and flow from the mill principle, making material achieve fine crush goal.

2. Wood powder making machine composed by rotor, top frame and bottom frame three part. Grinding chamber adopt multistage crushing process and fine crushing principle device, it's features: big working impact force, high production efficiency, strength fine crush ability.

3. The machine consist of main host, blower, analyzer, powder collector, dust collector and other spare parts. Each part has features of compact structure, reasonable layout, easy operation, low noise, etc.

Wood powder making machine installation introduction:

1. The machine should lay on the concrete base that was pre-made, after calibrated the machine horizontal line, then pour foot bolts reserved hole by concrete, after concrete solidification then tighten foot bolts again.

2. After wood powder making machine installed, it should have electric protection device, after electrician wiring then testing, all the electricity controlled by power distribution.

2014年4月10日星期四

High Pressure Suspension Grinding Mill Reducer Introduction:

I. High pressure suspension mill reducer brief introduction:

Reducer is a kind power transmission device, using gear speed converters, making electric BW type foot board horizontal installed double shaft cycloid pin wheel reducer to get revolution number, and achieve big torque structure. At present, using for transmission power device, reducer is widely. Amost using in all different kinds machinery transmission system.

II. High pressure suspension grinding mill reducer main function:

1. Reduce speed at the same time decrease loading inertia, reduce speed rate squared is inertia amount. As we all know, generally, all the motor have a inertia values.

2. Reduce speed at the same time improve output torque, torque output proportion according motor output multiply reduction ratio, but you should note that it can't exceed reducer rated torque.

III. High pressure suspension grinding mill reducer working principle:

Reducer generally used in low speed big torque transmission equipment, let motor or other high working speed power through reducer input shaft fewer teeth gear mesh output shaft big gear to reach reduce working speed goal, general reducer also have many pair same principle gear to get ideal reduce speed effect, big gear and pinion teeth number ratio is transmission ration.

2014年4月9日星期三

High Pressure Suspension Grinding Mill Application:

High pressure suspension grinding mill description:

High pressure suspension mill is a new research and development mill by kefan based on many years powder grinding mill experience, according to the practical situation of the customers, and powder grinding mill industrial needs, which opens a new period of international powder grinding mill industry with high efficiency and low power consumption.

As a widely used powder grinding mill machine: high pressure suspension grinding mill. I think all of us know the basic knowledge of it, today, I'd like to introduce about high pressure suspension grinder application knowledge, hope I can do help to you to know much more about it.

1. High pressure suspension grinding mill applicate in material grinding industrial. No matter media crush raw material or fine grind material, all the process can be finished by high pressure suspension grinder.

2. High pressure suspension mill used in ore beneficiation industrial. During ore beneficiation industrial process, you should grind raw ore to fine powder; While it can not only used for pre-grinding, but also can mix using with ball to powder grind raw ore.

3. The machine suitable used in oxidation ball block industrial. as high pressure suspension grinder significant technology advantages, so, it can completely replace powder grinding mill machine used in oxidation ball block industrial.

4. High pressure suspension grinding mill used in construction material industrial. According to the date, it's used to deal with cement clinker, bauxite and limestone and other materials powder grinding process.

High pressure suspension mill is a new research and development mill by kefan based on many years powder grinding mill experience, according to the practical situation of the customers, and powder grinding mill industrial needs, which opens a new period of international powder grinding mill industry with high efficiency and low power consumption.

As a widely used powder grinding mill machine: high pressure suspension grinding mill. I think all of us know the basic knowledge of it, today, I'd like to introduce about high pressure suspension grinder application knowledge, hope I can do help to you to know much more about it.

1. High pressure suspension grinding mill applicate in material grinding industrial. No matter media crush raw material or fine grind material, all the process can be finished by high pressure suspension grinder.

2. High pressure suspension mill used in ore beneficiation industrial. During ore beneficiation industrial process, you should grind raw ore to fine powder; While it can not only used for pre-grinding, but also can mix using with ball to powder grind raw ore.

3. The machine suitable used in oxidation ball block industrial. as high pressure suspension grinder significant technology advantages, so, it can completely replace powder grinding mill machine used in oxidation ball block industrial.

4. High pressure suspension grinding mill used in construction material industrial. According to the date, it's used to deal with cement clinker, bauxite and limestone and other materials powder grinding process.

2014年4月8日星期二

Raymond grinding mill feeding system and grinding system composition:

Feeding rolls speed testing: raymond grinding mill automatic control system, feeding rolls speed range is from 30r/min to 300 r/min, lower speed testing method can adopt measuring cycle method. Feeding rolls speed adjust good or not effect whether feeding rollers can uniform feeding or not, at the same time, determined whether raw material flow layer along the whole grinding rolls length thickness. Only when feeding roll adjust to the certain speed, we can make sure raymond grinding mill stable working, otherwise it will effect the production capacity, products quality and lead to the machine unnecessary damage. Feeding effect factors: 1. feeding roller tooth type and feeding rolls working speed; 2. feeding capacity automatic adjust function.

Raymond grinding mill process flyash make clients get high profit:

With urbanization each basic construction fast speed development, cement, concrete and these raw material requirements large amount. This indicates that flyash has also very big utilization valuable, when our company many clients purchase raymond grinding mill, main used for deal with flyash, according our clients, outlet products with high profit, many of our clients are old customers, if without satisfactory harvest, how can they continue increase equipment, expand production?

Raymond grinding mill is one of kefan machinery flagship product, kefan has already researched raymond grinding mill for many years, has rich experience on mining equipment each aspect, clients can assured to purchase. Our company has many other heavy type equipments: lime rotary kiln, coal slime dryer, rotary drum dryer, high pressure suspension grinding mill, etc. Sincerely welcome clients to our factory inspect the machine you need.

Vertical grinding mill wearing parts:

1. Vertical grinding mill blade main used to material continue shovel into between grinding roller and grinding ring. When continue shovel up material, blade bear different quality, hardness material carry out long time contact friction, very easy suffering wear and tear, serious damaged blade can't shovel up material, lead to vertical grinding mill working efficiency suffering a certain degree effect. Thus, raymond grinding mill blade structure majority made by good wear resistance steel, make sure blade achieve the longest using life.

2. Vertical grinding mill grinding roller and grinding ring is the whole equipment wearing parts, after material transported between grinding roller and grinding ring, it will be pressed by grinding roller and grinding ring and rotarion force to achieve crushing function. So, grinding roller and grinding ring not only suffering material friction, but also suffering each other friction force. When grinding roller and grinding ring appear serious abrasion or uneven abrasion, it will effect material fine powder production, appear final products with uneven fineness phenomenon. To make sure final products fineness, vertical grinding mill grinding roller and grinding ring adopt high pressure high toughness wearable steel material, made the machine with much more widely application and for many kinds raw materials have better grinding function.

2014年4月7日星期一

Raw material effect raymond grinding mill grinding roller tooth number:

Raymond grinding mill production proved: compared with more gear tooth, fewer gear tooth will save much more energy, lower grinding temperature, longer grinding roller using life, can adapt high feeding capacity.

2014年4月3日星期四

Raymond grinding mill structure and working advantages:

Raymond grinding mill adopt domestic and foreign same kinds products advanced structure, at big scale raymond mill base update and improve designed. Powder making company autonomous research and development big, media, small scale new type energy-saving vertical grinding mill using modern design method, adopt advanced grinding theory to guide. Grinding roller designed at plum frame center line both side, making grinding roller device under natural balance condition, main host with stable working, low vibration.

Raymond grinding mill main host working chamber grinding roller with small volume, leave many more volume for grinding chamber, blower high pressure air flow capacity flow into more working area, lead to outlet fine powder have more chance fastly out of main host, flow into cyclone collector, avoid ultrafine powder repeat grinding for many times. That's new type energy-saving raymond mill production capacity high than general three roller vertical grinding mill reason. New type energy-saving raymond grinder only have two rollers, with low working load, compared with the same specification general three roller raymond mill saving 25% energy, production capacity improved 20%.

During further developing, vertical grinding mill with have futher development, to improve the structure and property.

2014年4月2日星期三

Cement cooler relative technology:

Cement cooler refractory material requires:

As temperature can achieve 1100 degree, so, cement clinker cooler inner wall must mosaic refractory material, the function is as high temperature resistant structure material and liner.

According to cement cooler working features and using requirements, refractory material should meet the following tips:

1. Material from 1100 degree high temperature fastly cooled to around 100 degree, refractory brick should anti-thermal shock and bear big temperature fluctuation;

2. Cement cooler should have good wearable property and bear raw material mechanical abrasion;

3. The equipment should have strong strength and resonable structure and anti-corrosion property under a certain temperature.

2014年4月1日星期二

Contact Raymond Mill Supplier For Discount!!!

Raymond grinding mill advantages:

According to data shows, among the domestic powder grinding machines, raymond grinding mill occupy over 70%. But why? The followings are the keys:

1. Compact structure and reasonable working, small footprint, vertical structure. Can form an independence production system;

2. Compared with other powder grinding mill plants, its final products rate achieve 99%;

3. Raymond grinder main host driving system adopt sealing gearing and pulley, smoothly driving and reliable operation.

4. Low dust pollution, eco-friendly, smoothly working.

5. Electromagnetic vibrating feeder uniform feeding raw materials, easy to adjust, energy-saving, easy to maintain, etc.

Many more details please check our website or contact us for raymond grinding mill discount!!!

Raymond grinding mill using precautions and features:

Raymond grinding mill together with the dust collecting equipment can obviously avoid the dust and noise pollution during raw material processing. Raymond mill has features of stable performance, high efficiency and low investment, etc.

Raymond grinding mill using precautions:

1. During raymond grinder working process, you can't add oil arbitrary to make sure safety working, when grinding mill machine any spare parts occurs abnormal noise or loading capacity suddenly increase, you should stop working and checking faults, avoid happen serious accident, after discharging excess material inner the raymond grinder then start working, otherwise the machine overcurrent and avoid starting.

2. Before raymond grinding mill start working, you should check whether all the access door tightly sealed or not. Checking whether crusher jaw board gap can meet feeding size requirement or not, adjust analysis machine speed should approximate final products size requirement. Raymond grinder simple working process: elevator --- crusher --- analysis machine --- blower --- main host --- feeder.

3. When raymond grinding mill stop working, you should first stop feeding, main host continue working and grinding residues materil, one minutes later, stop main host motor and analysis motor, stop grinding working, then stop blower motor to blow residual powder. Raymond grinder stop working sequence: feeder --- main host --- blower --- analysis machine.

订阅:

评论 (Atom)